Being in the purchasing arena for manufacturing for 20+ years, I was never very keen on manufacturer's representatives in the past. I didn't see the value that they could bring, until I started working with F.R. Burger & Associates. They are well-versed in materials and manufacturing concepts, they have an excellent book of principal manufacturers that can satisfy almost any manufactured component; with particular specialties in high tolerance, highly engineered components for industrial applications. They really work for their clients; helping to negotiate pricing, delivery, and always willing to step in to resolve quality concerns. I feel like they are looking out for my best interest as a client, not the manufacturers they represent. I highly recommend F.R. Burger & Associates.

- Doug Danziger, Director of Purchasing at Maxitrol Company

Our representatives provide more than 30 years in technical experience through our U.S. based principals and customers worldwide. From product design through production, we strive to provide our customers with competitive pricing, excellent service, and superior quality.

F.R. Burger & Associates provides engineering assistance, tooling design, processing alternatives, and material solutions through our certified suppliers of castings, stampings, rubber moldings, fabrications, and powder coaters.

Member of the North American Die Casting Association (NADCA).

CAPABILITIES

F.R. Burger & Associates offers a wide range of capabilities throughout multiple industries worldwide. Through innovative manufacturing strategies and processes we help to overcome many common production issues: shortening lead times, increasing product reliability, and reducing cost.

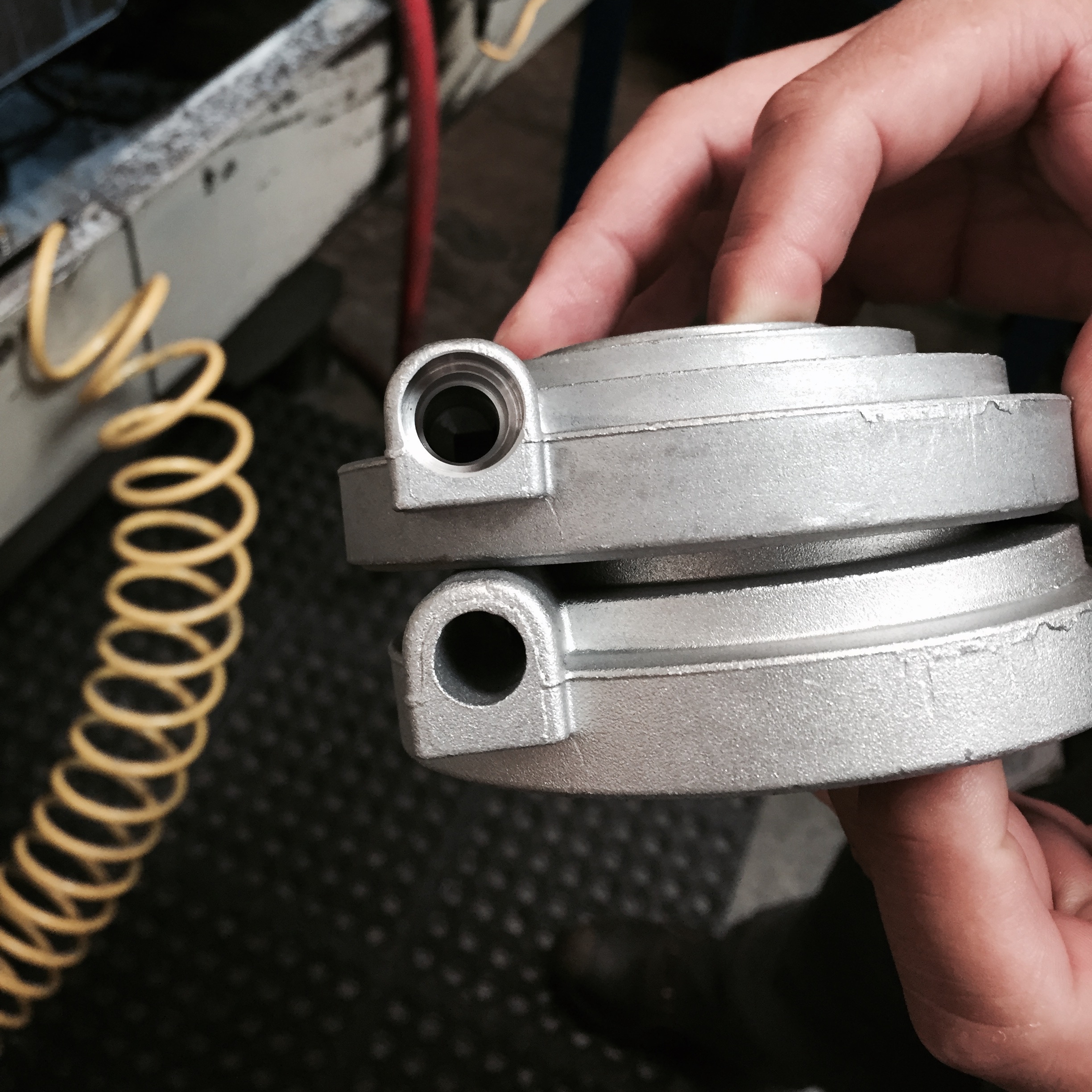

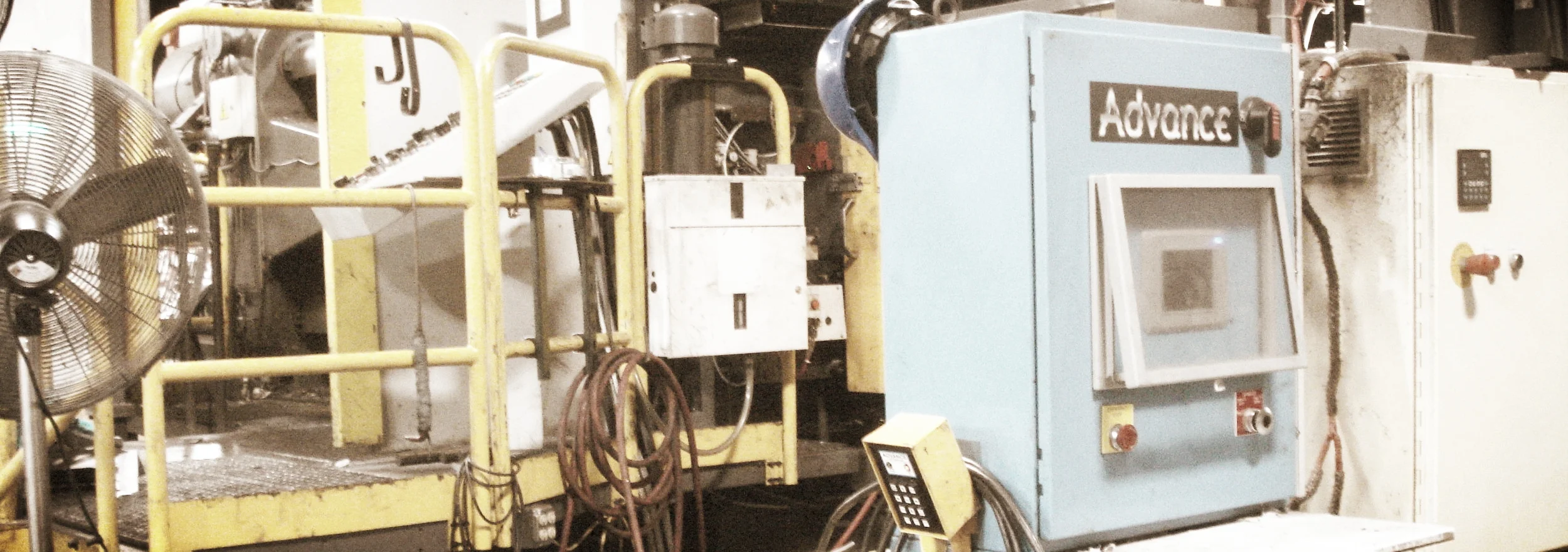

Castings

Worldwide resources to meet your quality production requirements

Processes in Sand, Permanent Mold, Die Cast, or Low Pressure

Metals range from Aluminum, Zinc, Magnesium, or Iron (Grey, Ductile, Austempered)

All materials are cast by a quality certified ISO or TS 16949 foundry

Machining

Machining includes: Aluminum, Steel, and Iron (Ductile, Grey, Austempered)

Our CNC centers accommodate production runs of all types

Operations perform: Milling, Drilling, Tapping, Turning, Boring, Profiling and Broaching

ISO/TS Certified

Engineering

Mastercam (CAD/CAM)

Pro-E

SolidWorks

SolidEdge

Kubotek KeyCreator

Part and Tool Design

Equipment and Fixture Design

Plastic Injection

A compact operation with tonnage range from 18-300 ton

Secondary operations include: Machining, Sonic Welding, Hot Stamping, and Assembly

Ability to run all injectable materials in any quantity required

Powder

Low to medium volume

High volume (Nordson Painting Systems)

Castings, Stampings, Weldments, Steel or Aluminum plates up to 18″ wide and 30″ long

Our powder suppliers create the exact color match for your part

E Coat

Standard black e coat applications

Protection from 500-1000 hours of salt spray testing

Based on quantity, we offer a variety of e coat colors

Rubber Molding

Versatile molding options are available: Injection, Compression, Transfer, and Extruding

To ensure concise and accurate parts, finishing consists of Nitrogen Shot Blasting, Tumbling, Die Cutting, and Wheel Trim Cutting

ISO 9001: 2015 Certified

Stampings & Fabrications

Sheet metal operations include: Press Brakes, Laser Cutting, Presses, Turret Punch Presses, and Welding

CNC machining centers complete the part before assembly and final painting

TS-16949 and ISO-14001 Certified

INDUSTRIES

Appliance

Automotive and Trucking

Consumer Products

Defense

Electronics

Industrial

Lawn & Garden

Lighting

Medical

Power Tools

Pumps and Valves

Sports and Recreation

QUALITY ASSURANCE

ISO 9001: 2015

ISO 9001: 2008

ISO 14001: 2015

ISO/TS 16949: 2009

(PPAP) Production Part Approval Process

(APQP) Advance Production Quality Planning

(FMEA) Failure Mode and Effects Analysis

Lean Manufacturing

Flow Modeling

Thermal Analysis

Process Engineering

Vision Inspection Systems

Metallurgical Lab

In-House X-Ray Inspection

CORE VALUES

Collaboration - leverage collective genius

Continuous Improvement - always strive for perfection

Innovation - driving success

Integrity - be real

Sense of Urgency - vital timeliness

OFFICE

F.R. Burger & Associates

29123 Millard Drive

Bay Village, OH 44140

Office/Cell: 440.668.8706

Email: fred@frburger.com

REQUEST A QUOTE

Please submit your project information and we will follow up to request supporting documentation.